Why Manufacturing Needs the Cloud

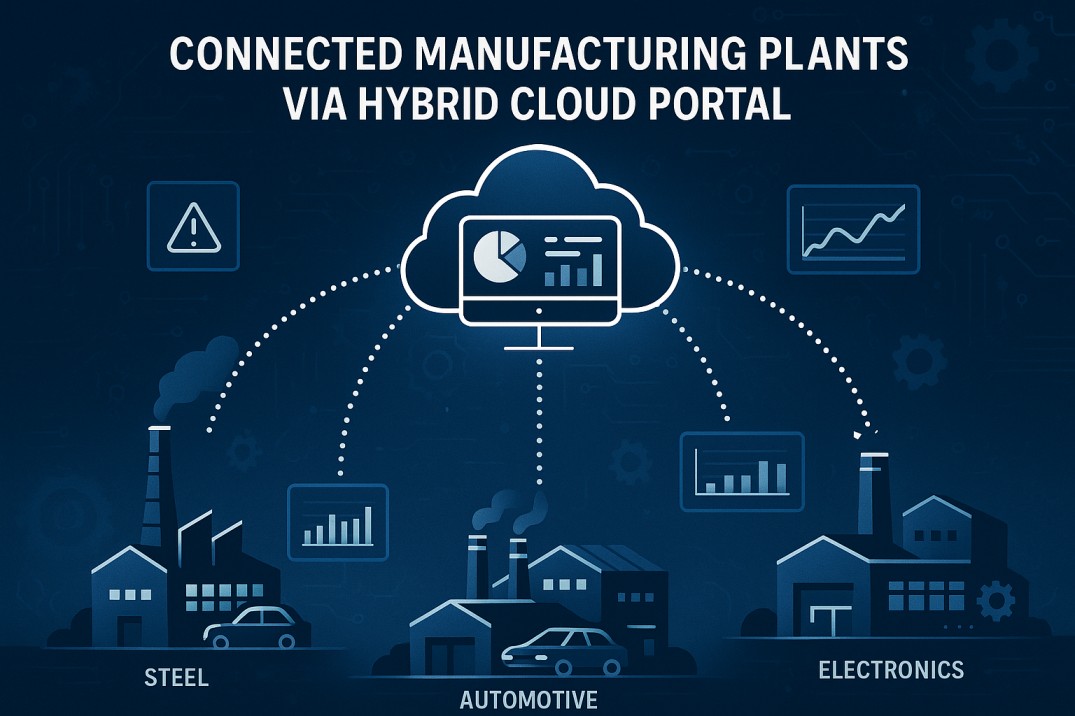

Manufacturers today face complex challenges. That’s why hybrid cloud web portals for distributed manufacturing are becoming essential. These portals help manage data, connect plants, and support smarter decisions in real time.Today, many companies have production plants spread across regions or countries. Their teams work in different places and at different times. Despite that, they still need to share data, talk to each other, and make fast decisions.

This is where hybrid cloud web portals play a key role. These portals use a mix of private and public cloud systems. They bring together data from different locations into one central, secure platform. Whether your team is on-site or remote, everyone can view the same real-time data.

For instance, an operator in one plant can update a machine status. At the same moment, a manager in another city can see that update. This level of visibility is powerful. It improves decision-making and prevents delays.

Without cloud systems, companies rely on outdated tools. Spreadsheets, email chains, or manual logs do not work anymore. They lead to confusion and slow decision-making. As operations grow more complex, these tools only make things worse.

Recent research by McKinsey highlights this challenge. Their studies show that cloud-based manufacturing tools can improve productivity by 20 to 30 percent. They help teams move faster, track more data, and reduce downtime.

This article will explore how hybrid cloud portals solve these issues. You will learn how they work, their main features, and the real benefits they offer. We will also look at common use cases, security considerations, and industry best practices.

How Hybrid Cloud Web Portals for Distributed Manufacturing Work

A hybrid cloud web portal is an online control center for your manufacturing business. It connects private servers at your factory with public cloud platforms like Amazon Web Services, Microsoft Azure, or Google Cloud. This setup gives you full control of your data, while still enjoying the flexibility of cloud services.

In other words, your company can store critical data locally, such as machine settings or production records. At the same time, it can store less sensitive data or backups in the public cloud. The hybrid cloud portal combines both and displays them in one easy-to-use interface.

This portal is accessible from any device. Whether you use a desktop, tablet, or smartphone, you can check system status, monitor production, or chat with your team. All of this happens in real time.

For example, a plant manager can check the live temperature of a machine. An engineer can receive an alert about system performance. A logistics officer can track which orders are ready to ship. All this data is available through the same portal.

With this kind of system, teams are always aligned. They work smarter, not harder.

Key Features of Hybrid Cloud Web Portals for Distributed Manufacturing

A good hybrid cloud web portal is more than just a website. It includes several components working together to make the system fast, secure, and useful. Let us break it down.

- Public Cloud Services

These are global platforms like AWS or Azure. They handle storage, processing, and analytics. They offer unlimited space, flexible pricing, and quick setup. - Private Cloud or On-Premise Servers

These are servers owned by the manufacturer. They are usually located at a main plant. They store sensitive data, run critical apps, or support local machines. - Web Portal Interface

This is what your team sees. It shows dashboards, alerts, analytics, reports, and chat windows. It is designed to be easy to use and mobile-friendly. - Security Systems

Security is a top priority. These portals include firewalls, encryption tools, and access controls. They make sure only the right people can view or change data. - Edge Computing Devices

These small computers are placed near machines. They process data instantly and send only useful information to the cloud. This saves bandwidth and speeds up decisions.

Together, these components form a system that is smart, scalable, and secure.

For instance, if a sensor detects a machine vibration, the edge device processes it locally. If it senses a problem, it sends an alert to the cloud. The portal then notifies managers across all plants instantly. This kind of flow keeps operations running smoothly.

How Hybrid Cloud Web Portals Compare to On-Premise and Public Cloud Systems

Let us now compare hybrid cloud systems with traditional options. This helps you see the clear advantages.

1. On-Premise Systems

These systems run fully inside your facility. All data, machines, and apps are local. While they give you full control, they are expensive to set up and hard to maintain. Scaling is also difficult. If you open a new plant, you must install everything from scratch.

2. Public Cloud Systems

These systems use only cloud platforms. They are cheaper, easier to scale, and more flexible. However, they can raise security and privacy concerns, especially for factories that deal with intellectual property or sensitive data.

3. Hybrid Cloud Systems

These systems combine the best of both worlds. You get local control through private servers. You also enjoy the flexibility of public cloud services. This model is cost-efficient, scalable, and secure. It also lets you choose where to store each type of data.

Below is a simple comparison of the three models:

| Feature | On-Premise | Public Cloud | Hybrid Cloud |

| Initial Cost | High | Low | Medium |

| Scalability | Limited | Excellent | Excellent |

| Security | Very Strong | Moderate | Strong and Flexible |

| Speed | Fast (local) | Depends on network | Fast (local + cloud) |

| Flexibility | Low | High | Very High |

Most modern manufacturers now prefer hybrid systems. They support growth without losing control. They also reduce risk and simplify operations.

Why Distributed Manufacturers Are Choosing Hybrid Cloud Web Portals

Modern manufacturing is global. Today, a company might have five or more plants. These plants are in different cities, countries, or even continents. Although this approach offers flexibility, it also brings challenges.

Each plant often runs its own systems. Each site stores data separately. This setup makes it difficult for teams to share information. When teams are not connected, errors happen. Work slows down. Quality suffers.

Let us take a closer look at the problems and how hybrid cloud portals solve them.

Key Challenges in Distributed Manufacturing

- Data Silos

In many cases, every plant collects and stores its own data. But that data does not move across locations. Teams in one factory do not know what is happening in another. This disconnect creates confusion. It also slows down decision-making.

- Delays in Accessing Information

Manufacturing decisions depend on fast data. If reports or machine logs come late, issues stay hidden. For example, a delay in a machine part delivery might go unnoticed. This can cause production to halt across other sites.

- Poor Coordination Across Teams

When teams work separately, communication gaps appear. Staff in one plant might not know the production schedule of another. Without a central system, coordination becomes nearly impossible.

These problems can cost companies time, money, and even customer trust.

Real-Time Communication Through Hybrid Cloud Web Portals

Hybrid cloud portals eliminate silos. They connect every plant to a single digital platform. As a result, every user sees real-time information. Everyone knows what is happening at all times.

For instance, if a machine breaks down in one location, the system can alert others. This allows teams to shift resources or adjust schedules. It reduces downtime and improves reaction time.

Also, alerts can be sent to managers instantly. Whether they are on-site or remote, they can take action without delay.

Hybrid Cloud Web Portals Enable Centralized Data with Local Control

Hybrid systems offer a perfect balance. They allow the central office to see all operations at once. At the same time, they let local teams keep control of their specific tasks.

Local staff can manage their machines, view performance, and update schedules. Meanwhile, upper management tracks KPIs across all plants in real time. Everyone works from the same source of truth.

This centralized yet flexible setup builds trust and encourages faster teamwork.

Better Compliance and Transparency

Regulations often require full production tracking. With a hybrid cloud portal, data is collected automatically. Reports are created without manual work. This makes audits easier and ensures nothing is missed.

Moreover, real-time visibility improves accountability. Everyone can see who did what, when, and why. This promotes better habits and reduces mistakes.

Real-World Use Cases of Hybrid Cloud Web Portals in Distributed Manufacturing

Now that we understand the need, let us explore the features that make hybrid cloud web portals so valuable.

-

Centralized Dashboards

A dashboard is like a control center. It shows key numbers in one place. This includes machine health, productivity, material use, and team status.

With a good dashboard, managers do not need to call or email different teams. They can check progress, spot delays, and take action immediately.

-

Edge-Cloud Data Syncing

Many manufacturers use edge computing. This means some data is processed near the machines. It reduces delay and speeds up actions.

The edge devices collect real-time data from machines. This data is then sent to the cloud. There, it is stored, analyzed, and shared across teams.

This approach offers both speed and accuracy. It ensures that even if internet speeds drop, local operations stay smooth.

-

Role-Based Access Control

Not all data should be visible to everyone. A hybrid portal supports custom access based on roles.

For example, operators see machine settings. Maintenance staff see service alerts. Managers see reports and analytics. Executives see high-level KPIs.

This ensures privacy, improves focus, and avoids data overload.

-

IoT Integration

The Internet of Things, or IoT, is now standard in smart factories. Machines are filled with sensors. These sensors measure heat, pressure, speed, and more.

The hybrid portal connects with these devices. It collects the data and shows trends,sends alerts and help you spot issues before they turn into failures.

For example, if a motor starts overheating, the system can alert your team. You can fix the problem before it causes a breakdown.

-

Cloud-Based Analytics

Data is only helpful when it is easy to understand. That is why analytics is key.

Hybrid cloud portals include built-in analytics tools. These tools turn raw numbers into simple charts and insights. You can see which line is slow and find waste in materials to track delivery times.

Even better, many systems allow you to create custom reports. You can choose what to track and how often. This makes your data work for your specific needs.

-

ERP and API Integration

Many factories already use tools like ERP or MES systems. A good hybrid portal connects with these systems.

It does not force you to change everything. Instead, it enhances what you already have.

APIs, or application programming interfaces, allow smooth data flow between systems. For example, when your ERP tracks inventory levels, the portal updates production plans automatically. This reduces manual work and lowers the chance of errors.

-

Mobile and Remote Access

Teams are not always at their desks. Some work on the shop floor. Others travel between sites. Hybrid cloud portals support mobile access.

Users can log in from phones or tablets. They can get alerts, check reports, or update tasks on the go. This flexibility makes the system useful for everyone, at all times.

-

Predictive Maintenance Features

Downtime hurts productivity. Predictive maintenance helps avoid it.

Using machine learning and sensor data, the system can predict when a machine may fail. It looks at temperature, pressure, and vibrations. When the numbers look risky, it sends alerts.

This allows your team to schedule service before a breakdown happens. It improves uptime and extends equipment life.

- Multi-Language and Multi-Currency Support

Global manufacturers often work across countries. That means different languages, rules, and currencies.

Many hybrid cloud portals offer built-in support for these needs. This includes language selection, local date formats, and currency conversion. It ensures smooth communication across borders.

-

Scalability and Customization

No two manufacturers are the same. That is why flexibility matters.

A hybrid portal should grow with your business. It should allow you to add new users, connect more machines, or include new features as needed.

You can start small with one site and expand as you see success.

Use Cases and Industry Examples

Hybrid cloud web portals are not just ideas or future trends. Many industries already rely on them every day. They use them to manage complex operations, boost efficiency, and improve visibility. Let us look at how three key industries benefit from hybrid cloud portals in real-world situations.

-

Automotive Industry

In the automotive world, everything moves fast and across locations. Vehicle manufacturers often manage dozens of plants across multiple regions. Some focus on assembly. Others handle engine manufacturing or parts supply. All these plants must stay in sync.

With a hybrid cloud portal, companies can connect all their factories. Engineers at the main office upload design updates to the cloud. Instantly, plants around the world access these changes. This reduces production delays and avoids errors caused by outdated information.

Moreover, suppliers and logistics teams also connect to the same portal. Everyone sees the same data and follows the same schedule. As a result, automotive firms avoid bottlenecks and late deliveries.

For example, if one plant completes production early, another can adjust its workflow. This level of visibility allows companies to shift priorities and optimize production in real time.

-

Electronics Manufacturing

Electronics manufacturers face extreme pressure to deliver quality and speed. Products like smartphones, circuit boards, or microchips have very short life cycles. Also, production often involves high-tech equipment and precision steps.

Hybrid cloud web portals help manage these complex operations. They track every component from design to assembly. If a sensor reports a drop in quality, the system alerts teams instantly. Technicians can stop production, identify the issue, and correct it.

Also, data from one plant helps other locations avoid repeating the same issue. This sharing of insights improves product quality across the entire network. When one factory learns something, the whole system learns too.

Additionally, customers and partners can get access to certain parts of the portal. This builds trust and makes collaboration easier, especially during audits or certifications.

-

FMCG and Consumer Goods

Fast-moving consumer goods (FMCG) industries work on tight schedules. Products like packaged foods, cleaning supplies, or health items must hit shelves on time. Delays can hurt sales and damage brand image.

Hybrid cloud systems help these businesses stay flexible. When one region sees a spike in demand, others can ramp up support. Factories share inventory data and balance production quickly. This avoids overstocking in one area and shortages in another.

Moreover, these companies often face seasonal demand. For example, soft drink production rises during summer. A hybrid portal allows fast scaling across plants. New staff can also access training tools via the portal.

Marketing, sales, and distribution teams get the same real-time updates. Everyone works with the same numbers and goals. As a result, FMCG companies move faster, make fewer errors, and reduce waste.

A Sample Workflow in Action

Let us walk through a sample production process. This helps explain how hybrid cloud portals improve operations across the board.

- A new product design is finalized by the engineering team

- The design is uploaded to the cloud portal by the project lead

- All factories receive instant access to the new specifications

- Machines in each plant adjust their settings automatically

- Teams begin production with full visibility across locations

- Managers track progress through dashboards updated in real time

- If any issues arise, alerts are sent and corrective action is taken

- Finished products are tagged and shipped with full digital records

This connected workflow saves valuable time. It cuts communication gaps and boosts quality. All of this happens through one central, hybrid cloud system.

Security and Compliance in Hybrid Cloud Web Portals

Security is critical in any hybrid cloud setup. Manufacturing operations deal with sensitive data like designs, production numbers, customer records, and supply chain details. If that data is lost or stolen, it can halt operations and damage your brand. A strong cloud security system helps prevent this.

Here are the key security and compliance points every hybrid cloud portal should include:

-

Data Encryption for Transfer and Storage

- All data should be encrypted before it moves or gets stored.

- Encryption makes your data unreadable to unauthorized users.

- Even if data is stolen, it cannot be used or understood.

- Both in-transit (moving) and at-rest (stored) data must be protected.

- This is essential when sharing data between remote sites or vendors.

-

Global Compliance Standards Standards

- Cloud systems must follow international security and privacy laws.

- ISO 27001: Sets rules for managing sensitive information securely.

- NIST Framework: Offers a trusted guide for cybersecurity defense.

- GDPR: Protects customer data in European regions.

- Compliance builds customer trust and ensures legal safety.

- It also helps win contracts with global clients who demand security.

-

Backup and Recovery Plans

- Accidents like system crashes, power loss, or attacks can happen.

- Cloud portals should have automatic backup systems in place.

- Backups should be stored both on-site and in the cloud.

- If one system fails, another can take over without data loss.

- This avoids downtime and keeps production running smoothly.

- Fast recovery helps reduce damage and control business risks.

-

Access and Authentication

- Only authorized users should access sensitive systems.

- Use multi-factor authentication and role-based access control.

- Different users get access to different tools and data.

- This reduces internal threats and keeps data safe from mistakes.

Integration with ERP and IIoT in Hybrid Cloud Web Portals

A hybrid cloud web portal should not work alone. It becomes more powerful when it connects with the tools you already use. This makes it easier for manufacturers to upgrade without starting from scratch.

Let us look at how hybrid cloud portals work with your current technologies.

✅ Connects to ERP, MES, and SCADA

- Most manufacturers use ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and SCADA (Supervisory Control and Data Acquisition) tools.

- The portal connects directly with these systems using APIs and secure data flows.

- You do not have to replace anything. Instead, your existing tools get better with real-time cloud access.

- For example, ERP can fetch real-time production data. MES can get quality metrics live. SCADA can show equipment status from multiple sites.

This smooth integration avoids downtime and keeps your workforce familiar with the tools they already know.

✅ IIoT Sensors in Machines

- Industrial IoT devices (IIoT) are smart sensors placed on machines.

- They collect data like temperature, vibration, speed, pressure, and power use.

- The portal captures this sensor data in real time.

- It helps detect faults before machines break down.

- It also supports predictive maintenance, reducing repair costs and downtime.

- Quality checks become easier as deviations are flagged early.

By connecting machines to the cloud, manufacturers gain full visibility and control over their operations.

✅ AI and Machine Learning Support

- The more data you collect, the more insights you can generate.

- The hybrid cloud system uses AI and machine learning to analyze large data sets.

- It finds hidden patterns in machine behavior or product quality.

- AI can suggest when to perform maintenance, adjust production schedules, or even reorder parts automatically.

- These insights help improve energy efficiency, reduce scrap, and shorten lead times.

AI turns data into value—quickly, accurately, and around the clock

Challenges and Best Practices

Even the best systems come with challenges. But the good news is, with careful planning, you can overcome most issues. Here are common challenges and best practices for successful implementation of hybrid cloud portals in manufacturing.

✅ Network Latency

- In remote areas, internet connections can be slow or unstable.

- This creates delays when accessing cloud data or dashboards.

- To solve this, use edge computing devices at each site.

- These devices process data locally before syncing with the cloud.

- This keeps your operations fast and reduces reliance on internet speed.

Using a hybrid cloud gives you the flexibility to operate both online and offline.

✅ Vendor Lock-In

- Some cloud providers lock customers into their platform.

- They use proprietary tools or formats that are hard to move elsewhere.

- This limits your flexibility and increases long-term costs.

- To avoid this, choose platforms that support open standards.

- Ask vendors about data portability, open APIs, and multi-cloud compatibility.

Selecting the right vendor from the start saves you time and money in the future.

✅ Workforce Training

- Employees might resist new technology.

- They may feel overwhelmed by unfamiliar dashboards or tools.

- Change takes time, but training can help smooth the process.

- Offer step-by-step guides, short video tutorials, and hands-on support.

- Set up help desks or internal champions who can assist others.

- Reward early adopters and celebrate success stories.

When people feel confident using the system, adoption improves, and results follow.

Why Hybrid Cloud Web Portals for Distributed Manufacturing Are the Future

Hybrid cloud web portals are not just another tool. They are a powerful shift in how manufacturers manage operations. They bring real-time insights, fast decision-making, and strong teamwork across all locations.

These portals help you see problems early and act fast. They cut downtime, reduce waste, and make teams more productive. They are built to work with your current tools, not replace them.

Security is strong. Compliance is built in. AI and sensors add more value. When used well, hybrid cloud systems help your company grow and adapt faster than ever before.

If you run multiple plants or manage a distributed manufacturing team, now is the time to upgrade. The future is connected, cloud-powered, and data-driven.

Want to explore hybrid cloud options for your factory?

Need help choosing the right platform?

Schedule a free demo or consultation today. Let us help you future-proof your factory.